Capabilities of an MCQ gas mixer

The capabilities of an MCQ gas mixer include:

- Gas Flow Control: MCQ gas mixers have built-in mass flow controllers that allow precise control of the flow rates of individual gases. This enables accurate and stable mixing of gases in the desired proportions.

- Gas Mixing Ratios: MCQ gas mixers can create gas mixtures with precise and adjustable ratios. They typically support multiple gas inputs and can generate mixtures with various composition ranges, from very low concentrations to high concentrations.

- Multi-Gas Compatibility: MCQ gas mixers can handle different gases, including both reactive and non-reactive gases. They are designed to work with a wide range of gases, such as nitrogen (N2), oxygen (O2), carbon dioxide (CO2), argon (Ar), helium (He), hydrogen (H2), and many others.

- Accuracy and Precision: MCQ gas mixers are known for their high accuracy and repeatability in gas mixture creation. They can achieve precise flow control, allowing for accurate gas ratios within tight tolerances.

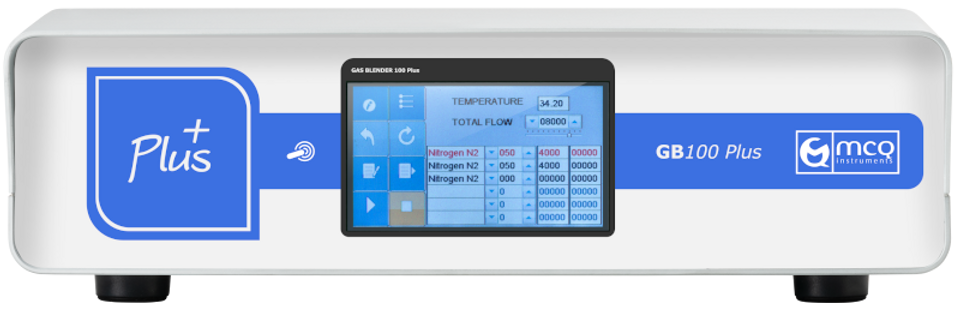

- User-Friendly Interface: MCQ gas mixers typically come with intuitive user interfaces that make it easy to set gas flow rates and mixing ratios. Some models may have digital displays or touchscreen interfaces for convenient operation and monitoring.

- Gas Safety Features: MCQ gas mixers often incorporate safety features to prevent gas leaks and ensure operator safety. These may include pressure sensors, leak detection systems, and emergency shut-off valves.

- Automation and Integration: Some MCQ gas mixers can be integrated into automated systems and controlled remotely. They may have digital communication interfaces like RS-232 or Ethernet, allowing for computerized control and data logging.

- Calibration and Maintenance: MCQ gas mixers usually require periodic calibration to maintain accuracy. They may have features for self-calibration or support calibration by the user or a qualified technician. Regular maintenance and cleaning are also necessary to ensure proper operation.